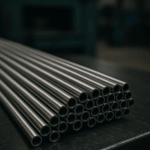

Stainless Steel Welded tubes

Kad Steel Brand Stainless Steel Welded erw tubes are made by rolling flat steel into a round shape and joining the edges using electric resistance welding. They have a strong, smooth weld and are known for their good strength, corrosion resistance, and uniform size. Common grades include 304, 304L, 316, and 316L, and they are used in many industries for their reliability.

TECHNICAL DETAILS:

| Specification | Details |

|---|---|

| Product Type | Welded Stainless Steel Pipes & Tubes |

| Standards | ASME/ASTM A249, A269, A312, EN 10217-7 (Equivalent to EN & DIN Standards) |

| Outer Diameter (O.D) | 21.3 mm to 219.1 mm |

| Nominal Bore (N.B) | 1/2″ NB to 8″ NB |

| Wall Thickness | 0.90 mm to 8 mm (SCH 5S, SCH 10S, SCH 20, SCH 40S) |

| Length | Up to 6 meters |

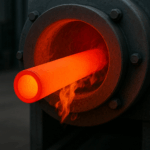

| Process Features | Gas Annealed, Pickled & Passivated |

| Surface Finish | Pickled, 2B |

| Material Grades | 304, 304L, 316, 316L Stainless Steel |

ADVANTAGES:

Stronag Weld Strength: High-frequency welding creates a solid and reliable joint.

Good Corrosion Resistance: Stainless steel material protects against rust and corrosion.

Smooth Surface Finish: Uniform and clean surface for easy handling and better appearance.

Accurate Dimensions: Consistent size and thickness for precise applications.

Cost-Effective Production: Efficient manufacturing process lowers overall production costs.